Precision CNC Machining & Manufacturing Solutions

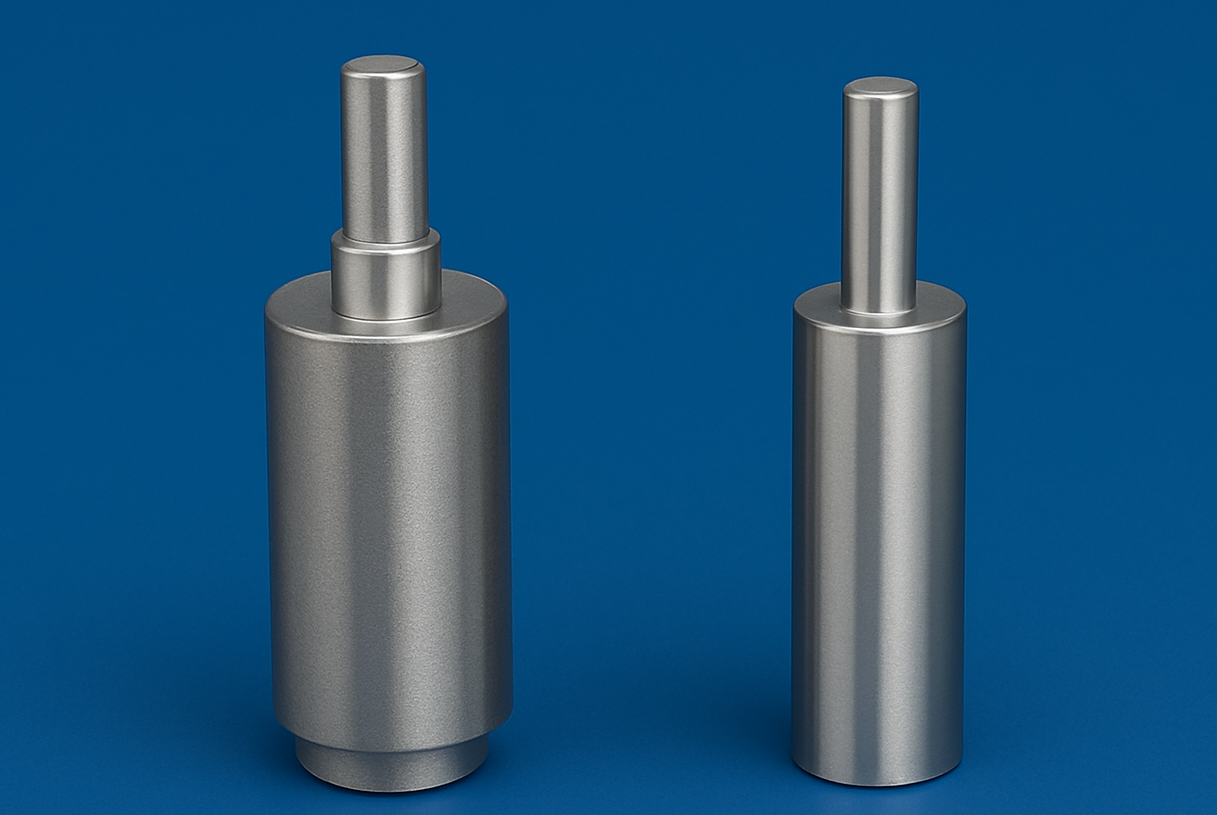

High-quality, tightly toleranced components for Aerospace, Medical, and Advanced Instrumentation Industries.

Our Services

-

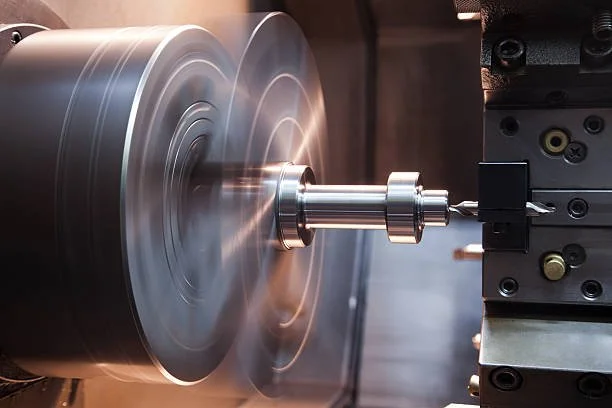

CNC Machining

We offer multi-axis CNC milling and turning for complex components requiring tight tolerances and consistent repeatability.

-

Conventional Machining

Our skilled machinists use precision lathes, grinders, and mills to produce small runs, prototypes, and specialty components.

-

Grinding & Honing

Centreless Grinding, Surface Grinding, and Honing deliver superior finishes and dimensional accuracy.

-

Tooling & Fixtures

We manufacture tooling, jigs, and fixtures to support specialized manufacturing processes and ensure precision during production.

-

Prototype to Production

Whether you need one-off prototypes or ongoing production runs, we provide flexible and cost-effective solutions.

-

Exotic Material Machining

From stainless steels to advanced polymers like Teflon, Delrin, and Vespel — we handle materials that demand expertise and care.

Our Capabilities in Action

Our shop includes:

3-Axis HAAS CNC Machining Centers (VF-3)

HAAS CNC Turning Center (SL-20)

Mazak and KOVO Precision Lathes

Jakobsen Surface Grinder and Cincinnati Centreless Grinder

Sunnen Honing Machine and Bridgeport Milling Machine

Vertical Saw – SHUR-CUT

All measuring tools are calibrated to ISO 9001 standards, ensuring consistent quality.

Quality Assurance

Every part we produce undergoes rigorous inspection and testing. Our processes are built on ISO 9001 standards to guarantee consistency, accuracy, and compliance with customer requirements.

Materials We Work With

Aircraft & Common Metals

• Aircraft Alloys

• Stainless Steels

• Carbon Steels

• Aluminum

• Bronze

• Copper

High-Performance Plastics

• Teflon

• Nylatron

• Delrin

• PVC / CPVC

• Vespel

Specialty Tool Steels

• H13

• D2

• A2

• M4

• M2

• 4140

• S7

• S1

• S5

• QRO

“How We Work”

Use a horizontal timeline or 4-step layout:

Consultation: Understanding your design and performance requirements.

Prototyping: Rapid turnaround on samples and test pieces.

Production: High-volume, repeatable machining with tight tolerances.

Quality & Delivery: ISO 9001 checks and on-time shipment.

Why Partner with Alpine Machining

Expertise in both CNC and conventional machining

Skilled team experienced with high-precision components

Proven track record across aerospace, medical, and instrumentation industries

Commitment to long-term, mutually beneficial partnerships

No results found

Contact

Let’s work together. Fill out the form below and our team will get back to you with answers, quotes, or more information about our services.

Phone

(905)-226-6252

Email

info@amtco.ca

engineering@amtco.ca

Address

5100 Maingate Dr, Mississauga, ON, L4W 1X6, Canada